Rochester Quadrajet Identification Guide for Corvette C3 (1968–1981)

This comprehensive guide to Rochester Quadrajet carburetor identification and operation covers everything Corvette C3 owners need, from part number decoding and key functions to recommended models for restoration

Enter the part number of your carburetor to get more detailed information about it.

| Quadrajet part number |

|

|---|---|

| Quadrajet date code |

|

| Carter date code |

|

The Rochester 4M-series Quadrajet carburetor was introduced in 1966 as a mechanical model. These carburetors were designed to provide efficient fuel consumption and adaptable performance for engines of various sizes and power outputs across different operating conditions. By 1975, modifications were made to meet stricter emission standards, but the carburetor remained fully mechanical (M4MC). In the early 1980s, electronic versions were introduced, featuring computerized control of the primary jets and throttle position sensors (E4MC).

The Quadrajet is known for its versatile fuel flow and effective design. The basic version was commonly calibrated for a flow rate of 750 cfm (cubic feet per minute), though some specialty models in the early 1970s were built with larger secondary barrels, allowing for 800 cfm.

Quadrajet’s efficient design balances the primary and secondary throttle bores, with components like the accelerator pump in the primary circuit and a vacuum-controlled secondary air valve. These features contribute to excellent fuel economy, rapid throttle response, and a properly balanced fuel mixture, even at peak power output.

The Chevrolet Corvette C3 featured Rochester Quadrajets from 1968 to 1981, while high-performance models from 1968 to 1974 were equipped with Holley carburetors. In 1982, Crossfire Injection was introduced, and no carburetor options were available.

| Year | Carburetor Used |

|---|---|

| 1968–1974 | Rochester Quadrajet, Holley (high-performance models) |

| 1975–1981 | Rochester Quadrajet |

| 1982 | Crossfire Injection (no carburetor) |

The electronically controlled Rochester Quadrajet was used in 1980 Corvettes exclusively in California models equipped with the LG4 305 engine and became standard in all 1981 Corvettes.

Identification

Rochester 4M-series carburetors can be identified through their model numbers. The number "4" in the model denotes a four-barrel (Quadrajet) carburetor. Letters such as "M" or "E" preceding the number indicate whether the carburetor has a mechanical or electronic air/fuel mixture control system. The letter following the 4M number signifies the type of automatic choke used.

| Model | Years | Type | Choke Description |

|---|---|---|---|

| 4M | 1966–1969 | Mechanical | Manual choke |

| 4MV | 1966–1969 | Mechanical | Bimetal coil choke in the intake manifold |

| 4MC | 1970–1975 | Mechanical | Manifold-heated choke on the carburetor |

| M4MC | 1975–1980 | Mechanical | Manifold-heated choke on the carburetor |

| M4ME | 1975–1980 | Mechanical | Electric choke on the carburetor |

| E4MC | 1980–1990 | Electronic | Manifold-heated choke |

| E4ME | 1980–1990 | Electronic | Electric choke |

These carburetors were used across various car brands and marine engines.

Identify your Quadrajet

The Rochester Quadrajet part number is located on the side or top of the carburetor, near the fuel inlet. It is stamped or etched into the metal and is a 7- or 8-digit code, depending on the model year.

The table shows how the Quadrajet part number is structured:

| Category | 70 Series (Pre-1975) | 170 Series (Post-1975) |

|---|---|---|

| Prefix | 70 - Indicates Rochester carburetors (First two digits) | 170 - Indicates post-1975 Rochester carburetors (First three digits) |

| Decade Code | 2 = 1966-1969 (Third digit) | 5 = 1975-1979 (Fourth digit) |

| 3 = 1966-1969 California (Third digit) | 8 = 1980 and later (Fourth digit) | |

| 4 = 1970-1975 (Third digit) | ||

| Year Code | 6 = 1966 (Fourth digit) | 5 = 1975 (Fifth digit) |

| 7 = 1967 (Fourth digit) | 6 = 1976 (Fifth digit) | |

| 8 = 1968 (Fourth digit) | 7 = 1977 (Fifth digit) | |

| 9 = 1969 (Fourth digit) | 8 = 1978 (Fifth digit) | |

| 0 = 1970 (Fourth digit) | 9 = 1979 (Fifth digit) | |

| 1 = 1971 (Fourth digit) | 0 = 1980 (Fifth digit) | |

| 2 = 1972 (Fourth digit) | 1 = 1981 (Fifth digit) | |

| 3 = 1973 (Fourth digit) | 2 = 1982 (Fifth digit) | |

| 4 = 1974 (Fourth digit) | 3 = 1983 (Fifth digit) | |

| 5 = 1975 (Fourth digit) | 4 = 1984 (Fifth digit) | |

| Emissions Code | 0, 1, 2 = Federal, 3, 4, 5 = California (Fifth digit) | 0-5 = Federal, 6-9 = California (Sixth digit) |

| Division Code | 0, 1, 2 = Chevrolet, 3 = Cadillac, 4 = Buick, 5 = Oldsmobile, 6, 7 = Pontiac (Sixth digit) | |

| Transmission Code | Odd Numbers (1, 3, 5, 7, 9) = Manual, Even Numbers (0, 2, 4, 6, 8) = Automatic (Seventh/Eighth digit) | |

Carter-Manufactured Quadrajet Carburetors

Carter produced Quadrajet carburetors under contract with General Motors from the late 1960s through the late 1970s to meet high production demand. Although the Quadrajet was originally designed by Rochester, a GM division, Carter-built units were manufactured to the same specifications and were identical in both function and design. These carburetors typically feature text indicating they were manufactured by Carter Carburetor for GMC, and the date codes differ from those used by Rochester.

Quadrajet Functions

The carburetor performs several important functions. It controls airflow to the engine to regulate power output, mixes air and fuel in the correct proportions for optimal engine operation, and helps vaporize the air/fuel mixture for efficient combustion.

For a more in-depth understanding of carburetor operating principles, consider acquiring literature on Quadrajet carburetors, with good options available in the Corvette C3 Books article. The following section outlines the key functions of the Quadrajet carburetor.

Inlet System

The inlet system manages fuel delivery to the carburetor. The fuel bowl acts as a reservoir that supplies fuel to the carburetor, ensuring a steady supply for engine operation. Fuel enters the fuel bowl through a filter, which helps remove contaminants and ensures clean fuel enters the system.

The fuel level in the bowl is regulated by the float, which moves in response to fuel levels, and an inlet valve that controls fuel flow from the fuel line. This inlet valve is composed of a needle and seat, which work together to open and close the valve, maintaining the correct fuel level. When the fuel level drops, the float lowers, opening the needle valve to allow more fuel in. As the fuel level rises, the float closes the valve, preventing overflow.

Main Jet System

The main jet system supplies the appropriate amount of fuel during normal driving conditions, from off-idle to wide-open throttle, maintaining a balanced air-fuel ratio across various engine loads and throttle positions.

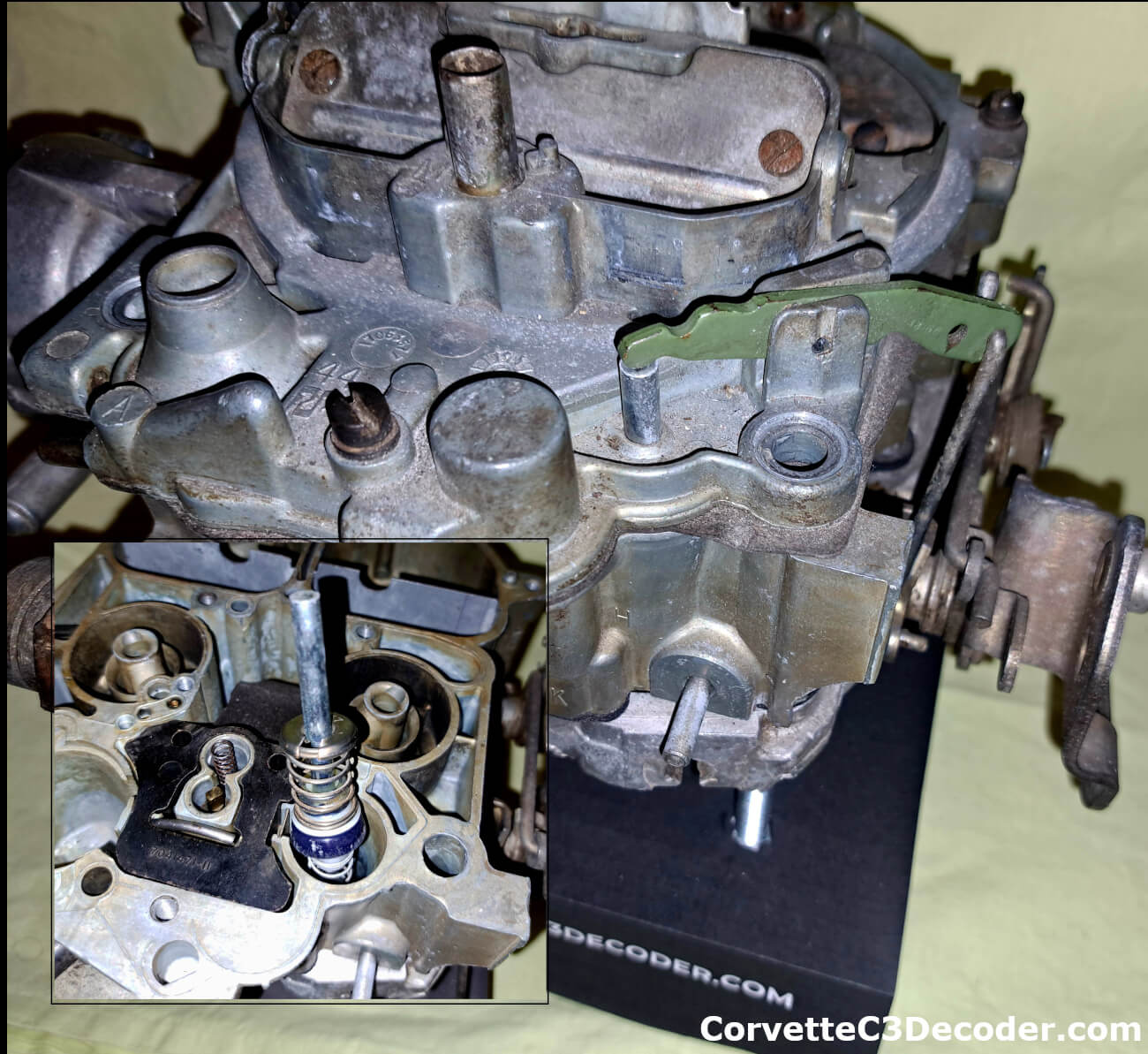

At the core of this system are jets (see image above), small calibrated openings that regulate fuel flow based on engine demands. Primary metering rods, controlled by the power system, adjust the jets by opening or closing them as needed.

As the driver presses the accelerator, the throttle plates open, increasing airflow into the intake manifold and reducing manifold vacuum. Under light throttle, the vacuum remains high, keeping the fuel mixture lean for efficiency. However, during hard acceleration or high load, the vacuum drops further, triggering the power piston to lift the metering rods and open the jets, increasing fuel flow. This enriched mixture prevents detonation and provides the extra fuel needed for optimal performance.

The choke plate is an essential part of both the primary and choke systems. It regulates the airflow into the carburetor during cold starts. When the engine is cold, the choke plate remains partially closed, restricting air intake and creating a richer fuel mixture to aid combustion. As the engine warms up, the choke gradually opens, allowing more air in and restoring the optimal air-fuel ratio for normal operation, while in this state, it serves as the source of air for the main jet system.

Secondary Jet System

Unlike mechanically linked secondary throttle plates, the secondary air valve remains closed under normal driving conditions. When the engine requires additional airflow—such as during heavy acceleration—the drop in manifold vacuum triggers the secondary air valve to open gradually. As the secondary air valve opens, it also moves the secondary metering rods, which are connected to the valve mechanism. These rods control the flow of fuel through the secondary jets, enriching the mixture as more air enters. As the rods lift, they allow a greater volume of fuel to pass through the jets, ensuring the engine receives the correct air-fuel ratio for maximum power output. This vacuum-actuated system provides a seamless transition between cruising and high-power operation.

Idle Circuit

The idle circuit is essential in managing fuel flow when the engine is operating at low speeds or idling. At these low RPMs, the throttle plates are almost fully closed, and airflow through the carburetor is minimal. Under these conditions, the engine relies heavily on the idle circuit to supply the necessary fuel for combustion, ensuring smooth operation and preventing stalling.

Fuel for the idle circuit is drawn from the float chamber, where it travels through the idle tubes. These tubes are precisely calibrated to regulate the fuel flow required for idle conditions. The fuel then exits via the idle discharge ports located in the primary barrels of the carburetor, positioned near the throttle plates, allowing a small amount of the fuel-air mixture to enter the engine even when the throttle is nearly closed.

The ratio of air to fuel at idle is controlled by idle mixture screws, which allow fine-tuning of the mixture to ensure optimal combustion. Adjusting these screws affects the richness or leanness of the mixture, providing the ability to dial in smooth idling based on engine requirements. Proper balance between air and fuel is critical to maintaining a stable idle, as too much fuel (rich mixture) can cause rough running and excessive emissions, while too little fuel (lean mixture) may lead to hesitation or stalling.

Choke System

The function of the choke system is to support cold starts and speed up engine warm-up, ensuring better drivability while helping to reduce fuel consumption during this critical phase.

Quadrajet carburetors feature a choke system that can be either mechanical, using a bimetal coil, or electric, utilizing a heating element to control the choke plate. The bimetal coil contracts when cold, causing the choke plate to close. This limits airflow into the carburetor, enriching the fuel mixture by allowing more fuel relative to air to enter the engine.

As the engine gradually warms up, the bimetal coil expands, slowly opening the choke plate and allowing more air to flow into the carburetor, balancing the air/fuel mixture. On electric choke systems, an electric heating element is activated by the ignition system, providing a controlled, gradual opening of the choke plate.

Quadrajet carburetors feature a vacuum-operated choke pull-off that partially opens the choke plate upon engine start, preventing an excessively rich mixture that could lead to flooding or rough idling.

The fast idle function in the choke system increases engine speed during cold starts to prevent stalling and improve warm-up efficiency. When the choke is engaged, a fast idle cam holds the throttle slightly open, allowing more air and fuel to enter the engine. As the engine warms up, the choke gradually disengages, lowering the idle speed to normal levels.

Accelerator Pump System

The accelerator pump system provides an extra burst of fuel when the throttle is opened quickly, ensuring smooth and responsive acceleration. When the throttle is rapidly increased, the intake air volume rises sharply, potentially leading to a lean condition if not compensated for by additional fuel. The accelerator pump counters this by injecting a small, controlled amount of fuel into the carburetor during this rapid throttle movement.

Recommended Quadrajet Carburetors for Corvette C3

Here is a list of recommended Quadrajet carburetors that are suitable for any Corvette C3, compiled by Quadrajet expert Lars Grimsrud. AT carburetors typically come with additional linkage for the kick-down function, which is essential for most automatic transmissions, and may also include an extra vacuum port. In some cases, AT carburetors are tuned for smoother, more stable idling and improved throttle response at low speeds. However, these carburetors are generally interchangeable with others.

| Part Number | Make/Model | Year | Transmission | Notes |

|---|---|---|---|---|

| 17056200 | Chevrolet Full Size | 1976 | AT | |

| 17056202 | Chevrolet Camaro | 1976 | AT | Federal |

| 17056203 | Chevrolet Camaro | 1976 | MT | Federal |

| 17056206 | Chevrolet Corvette/Nova | 1976 | AT | |

| 17056207 | Chevrolet Corvette/Nova | 1976 | MT | |

| 17056208 | Chevrolet Truck C10 | 1976 | AT | Federal |

| 17056209 | Chevrolet Truck C10 | 1976 | MT | Federal |

| 17056210 | Chevrolet Corvette | 1976 | AT | Federal, High Performance |

| 17056211 | Chevrolet Corvette | 1976 | MT | Federal, High Performance |

| 17056226 | Chevrolet Corvette | 1976 | AT | Federal, High Performance, A/C |

| 17056228 | Chevrolet Monte Carlo/Chevelle | 1976 | AT | |

| 17056281 | Chevrolet Chevelle/Camaro | 1976-77 | MT | Canada |

| 17056282 | Chevrolet Nova/Corvette | 1976 | AT | Canada |

| 17056286 | Chevrolet | 1976 | AT | Canada |

| 17056502 | Chevrolet Camaro | 1976 | AT | California |

| 17056503 | Chevrolet Camaro | 1976 | MT | California |

| 17056506 | Chevrolet Corvette/Nova | 1976 | AT | California |

| 17056507 | Chevrolet Corvette/Nova | 1976 | MT | California |

| 17057202 | Chevrolet Chevelle/Monte Carlo/Corvette | 1977 | AT | |

| 17057203 | Chevrolet Corvette | 1977 | MT | Federal, Non-A/C |

| 17057204 | Chevrolet Chevelle/Corvette | 1977 | AT | A/C |

| 17057210 | Chevrolet Corvette | 1977 | MT | High Performance, Non-A/C |

| 17057211 | Chevrolet Corvette | 1977 | MT | High Performance, A/C & Non-A/C |

| 17057228 | Chevrolet Corvette | 1977 | AT | Federal, A/C |

| 17057502 | Chevrolet | 1977 | AT | California, Non-A/C |

| 17057504 | Chevrolet Vette/Nova | 1977 | AT | California, A/C |

| 17057582 | Chevrolet | 1977 | AT | High Altitude, Non-A/C |

| 17057584 | Chevrolet Monte Carlo | 1977 | AT | High Altitude, A/C |

| 17080228 | Chevrolet Corvette | 1980 | AT | L82 |

Continue Exploring

Decoders Hub

VIN and trim tag decoders, checks, and guidance for authenticity and data lookups.

C3 Years Hub

Spotter guides and model‑year differences with jump links to each year’s in‑depth pages.

Articles Hub

Technical guides, history deep‑dives, buyer notes, and special features for the C3 era.

Share Your C3 Knowledge

Have insights to share? We welcome your expert feedback, technical discussions, and Corvette-related stories. Your contributions help keep this Corvette community thriving! Join the conversation below.

Page last updated: January 2026