My 1976 Corvette

Hood Insulation

Adding Hood Insulation to My Corvette C3

When I bought my 1976 Corvette C3, I noticed it lacked hood insulation. That small detail caught my attention, and I decided to dig deeper into its history and eventually add it to my own car.

When It Became a Factory Feature

Early Corvette C3s (1968–1972) left the factory without hood insulation due to less stringent noise regulations. It wasn’t until 1973 that Chevrolet began installing it, influenced by the Noise Control Act of 1972, which pushed automakers to reduce vehicle noise levels. While the law didn’t mandate under-hood insulation, it shaped engineering decisions to include it in production. Chevrolet opted for fiberglass-based insulation, balancing durability and cost.

What It’s Supposed to Do

Hood insulation’s primary purpose is sound control, reducing engine noise inside the cabin and in external pass-by tests. It also serves other functions:

- Heat protection – It shields the fiberglass hood from engine heat, which can damage paint over time.

- Fire safety – In rare cases, insulation can slow the spread of an engine fire by smothering flames.

Interestingly, the original factory paint on 1968–1972 hoods typically held up without insulation. However, I found multiple examples on Corvette forums where repainted cars suffered visible heat-related paint damage.

Hood Insulation Across Model Years

Hood insulation design varied across C3 model years. For 1973–1975 models with cowl induction, the air cleaner was open against the hood, so the insulation had an opening to accommodate this. The number of retaining pins also changed: 11 pins for 1973–1975, 8 pins for 1976–1977, and 6 pins for 1978–1979.

Aftermarket Materials: Foam, Rubber, and Fiberglass

Aftermarket hood insulation for the Corvette C3 is widely available, offering a variety of materials beyond the factory-standard fiberglass. Three popular options are foam, rubber, and fiberglass:

- Foam: Foam-based insulation is lightweight and effective at sound dampening. It’s often easier to cut and shape to fit the hood’s contours, making installation simpler for DIYers. Some foam options come with a foil backing to reflect heat, providing excellent thermal protection for the hood’s paint.

- Rubber:Rubber-based insulation is denser and more durable, offering superior noise reduction and heat resistance. It’s less prone to degradation over time compared to foam, but it can be heavier and slightly harder to install due to its rigidity. Many rubber options are pre-molded for specific C3 model years, ensuring a precise fit.

- Fiberglass: Fiberglass insulation, similar to the factory-standard material, offers a balance of sound dampening and heat resistance. It’s durable and often designed to closely match the original look of 1973–1982 C3 models. While not as flexible as foam, it’s a popular choice for those seeking a near-original aesthetic.

All three options—foam, rubber, and fiberglass—are available through Corvette parts suppliers or eBay, often with Corvette logos for added aesthetic appeal. Some aftermarket hood insulations are attached using adhesive, offering an alternative to traditional pin-based installation for a cleaner look.

A great example of the adhesive version installation can be found on Luis's YouTube channel: Watch the installation here

.My Own Car’s Experience

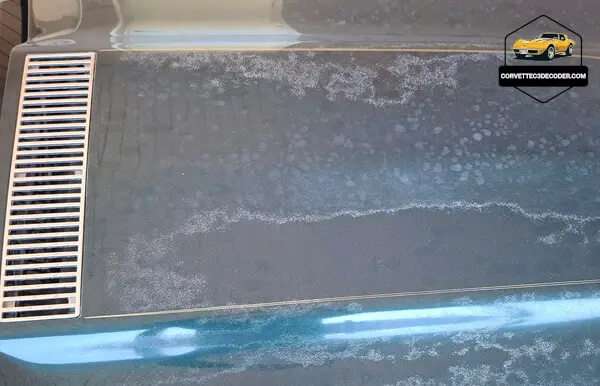

My Corvette was repainted over 20 years ago, and the hood shows heat-related paint variation—discoloration and rough clear coat damage. This convinced me to invest in insulation before repainting again.

I chose a basic, near-original fiberglass insulation that matches the 1976 aesthetic without overcomplicating things. The installation was straightforward. First, I used pliers to remove the retainers. After setting the new insulation in place, I secured it by aligning it and pressing the eight new retainers through it one by one, working from left to right. They fit snugly, and there was no need to make any holes or perform any similar preparation. I was able to simply press the retainers back in by hand to secure them. The whole process took about 10 minutes and only required a pair of pliers. One of the previous owners painted the retainers orange; I'll probably return them to black at some point.

Why Add Hood Insulation to Your Corvette C3?

Installing hood insulation on my 1976 Corvette not only reduced engine noise and protected my hood’s paint but also elevated the car’s overall appearance. This affordable upgrade, suitable for any 1968–1982 C3 owner, allows you to customize the look with options like Corvette logos or sleek, modern materials that enhance the under-hood aesthetic. Whether you choose foam, rubber, or fiberglass, you can tailor the insulation to match your style, making your Corvette stand out at car shows or in your garage.

Share Your C3 Knowledge

Have insights to share? We welcome your expert feedback, technical discussions, and Corvette-related stories. Your contributions help keep this Corvette community thriving! Join the conversation below.

Other articles

General

- Corvette C3 years

- Corvette Specs, Colors, etc. by year:

1968 1969 1970 1971 1972 1973 1974 1975 1976 1977 1978 1979 1980 1981 1982 - Is the Corvette C3 always a Stingray?

- Corvette C3 charts

- Corvette C3 books

- Mako Shark II

- Corvette L88

- Greenwood Corvettes

- Reader's Wheels: Corvette 1968

- Corvette C3 Buyer's Checklist